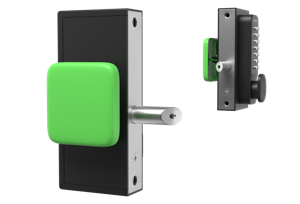

Product Description

The slim Superlock Quick exit Digital access is designed for when an easy exit from a gate is required. This version has digital keypad access from the outside, a key entry version is also available.

Key Features

- Secure – Stainless steel bolt that latches 15mm

- Adaptable – Slim 70mm case means this lock can suit a variety of different gate styles

- Reliable – Supplied with a bolt support plate to increase product life

- Available in two sizes – 1030 for 10 to 30mm flat bar or box section gate frames and 4060 for 40 to 60mm gate frames

- Use in conjunction with the Superlock keep to increase security and product life

- Fit the Superlock shroud to restrict access to the pad from outside the gate

Product Options

- BQDG1030L – For 10-30mm gate frames, Left hand

- BQDG1030R – For 10-30mm gate frames, Right hand

- BQDG4060L – For 40-60mm gate frames, Left hand

- BQDG4060R – For 40-60mm gate frames, Right hand

Installation

1. Drill 2 x 9mm holes at 140mm centres for fixing bolts provided.

2. Drill 18mm clearance hole for the latchbolt at 60mm centres up from the bottom fixing hole.

3. Hold the lock against the back of the box section and screw on the latchbolt through the 18mm hole.

4. Lock the latchbolt with the hex key supplied by inserting the hex key into the end of the latchbolt.

5. Fix lock in place using the stainless steel bolt support plate and the countersunk screws provided. Ensure the latchbolt moves freely.

6. Fix stike plate by either welding or screw fixing onto the gate post

7. MAINTENANCE Every 6 months, lubricate the latchbolt with light oil. Annually, dismantle the lock and spray mechanism with light oil.

Maintenance

3 monthly:

1. Remove keypads from the lock

2. Spray the inside of the lock thoroughly with WD40 or equivalent, through the

tumbler holes at the back of the lock

3. Spray all the fixing accessories and the latch with WD40 or equivalent.

Push each of the buttons and rotate the knob several times to make sure the

lock is working smoothly

To change the code

- Check the original code is working on both keypads To remove the keypads – Insert a flat screwdriver into the hole in the forend plate and lever out the keypad retaining plate. This will release one keypad. Slide out the lock mechanism and the other keypad can then be removed by accessing the screws through the lockcase.

- Turn the keypad over and remove the 4 red screws

- Lift off the covering panel. Be careful as there are 10 springs attached to this panel. Note that the red tumblers relate to the code shown above. Also note that the C tumbler is uncoloured and should not be removed.

- To change the code hold the keypad with the code buttons down and depress & hold the C button (if this is not done you may damage some of the internal components). Reposition the tumblers to the new code (red tumblers are coded and blue tumblers are uncoded). Ensure that the square cut-out on each tumbler is facing the outside of the lock body, also ensure that the coloured mark is facing upwards. If any one tumbler is upside down or the wrong way round the lock will not work and if forced will break the internal components. The code must always start with a ‘C’

- Replace the covering panel and tighten the 4 red screws.

- The code is now changed, check to see that it is working correctly and make a note of the code for future reference. Once satisfied that the lock is working correctly refit keypads to the lock case.